Conclusion

Personal protective equipment plays an indispensable role in protecting employees, but only within the right framework. Occupational health and safety strategy and working conditions legislation make it clear that true safety begins with eliminating risks at source. PPE is the last, but sometimes necessary, line of defense. Respecting this order not only creates a safer workplace, but also a more sustainable and professional safety policy.

“True safety begins with eliminating risks at the source. PPE is the last, but sometimes necessary, line of defense”

Foto: KNRM

Responsible use in practice

When PPE is necessary, the Working Conditions Act sets clear requirements. The employer must provide suitable equipment, tailored to the risk and the wearer. In addition, instruction is mandatory: employees must know when, how, and why they use PPE. Maintenance and replacement are also crucial; worn or contaminated equipment loses its protective effect.

Employees, in turn, have a duty to actually use PPE and to handle it with care. After all, working safely is a shared responsibility.

Why PPE is the last resort

Personal protective equipment protects the employee, but does not eliminate the danger. Moreover, it is highly dependent on correct use. Safety glasses that do not fit properly, a mask that is worn incorrectly, gloves that are not replaced in time, or a life jacket whose crotch strap is not used, offer a false sense of security.

PPE can also be burdensome: it can make work more difficult, restrict vision, or reduce comfort. This increases the likelihood that it will not be used consistently. That is precisely why the legislator emphasizes that PPE should never be an excuse for neglecting source or collective measures.

The law is clear on this point: risks should preferably be addressed at source. Only when this is not possible may additional measures be taken. Personal protective equipment is permitted, but only if other solutions do not offer sufficient protection.

The occupational health strategy as a guideline

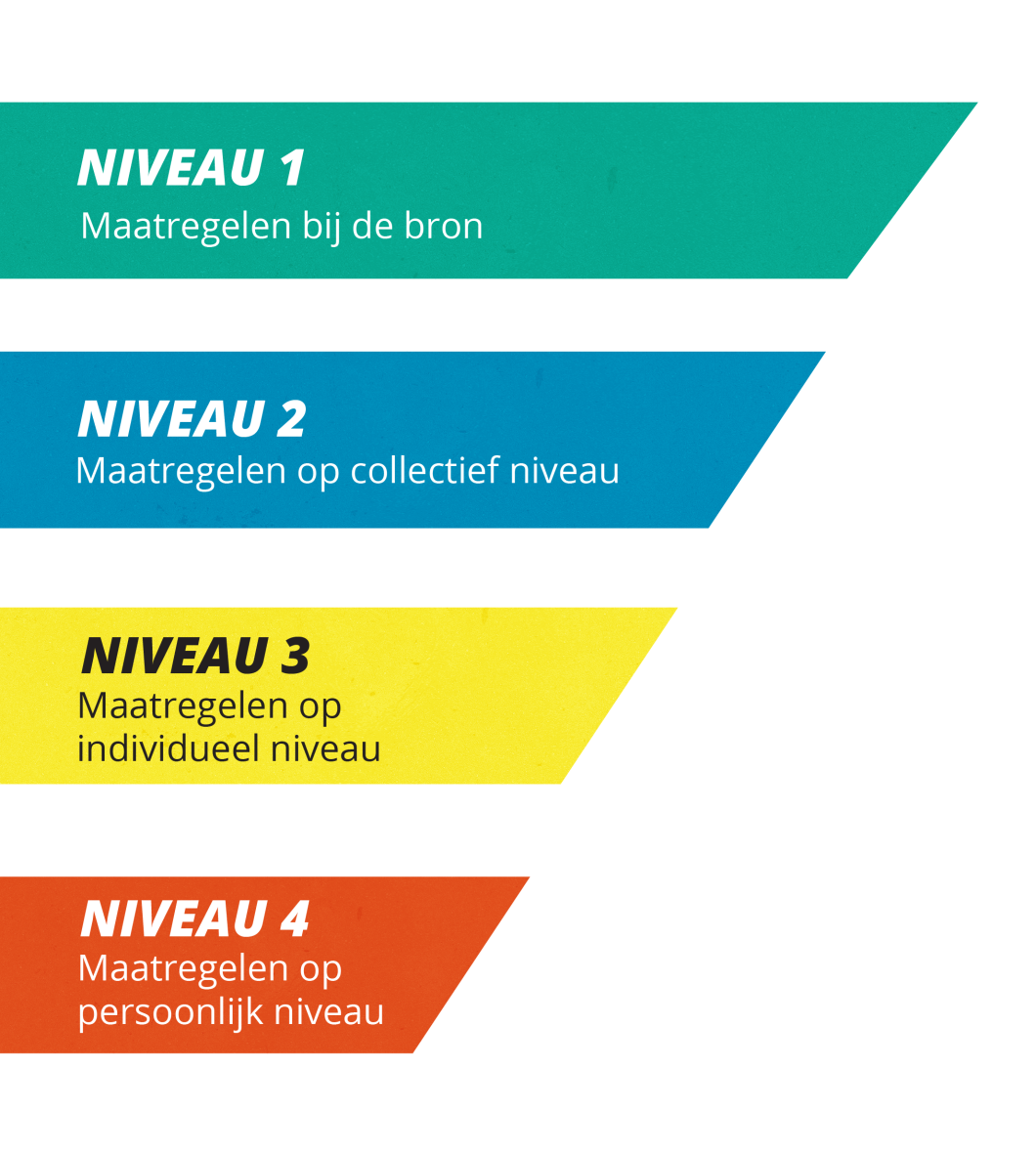

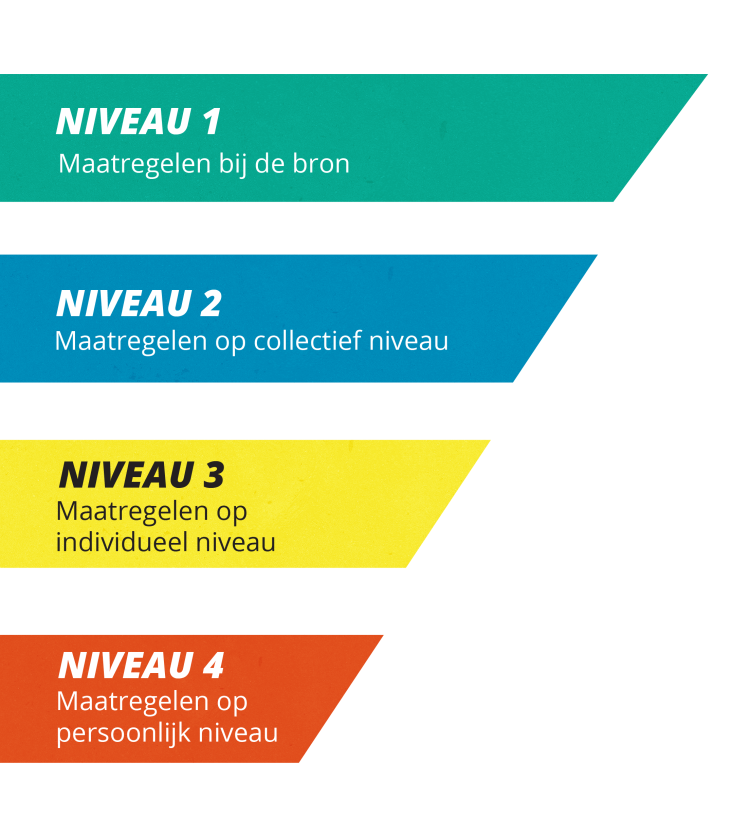

The occupational health strategy is the framework that helps you make the right choices in risk management. This strategy consists of a fixed sequence of measures:

Source approach

Eliminating the hazard itself, for example by replacing a harmful substance with a less hazardous alternative or by replacing a noisy machine.Collective technical measures

These include extraction systems, sound insulation, or physical shielding that protects multiple employees at the same time.Organizational measures

These include limiting exposure time, job rotation, or adjusting work processes.Personal protective equipment

PPE only comes into play when the above steps are insufficient.

This order is not arbitrary. It reflects the principle that structural solutions are more sustainable and reliable than protection that depends on individual behavior.

“Personal protective equipment protects the employee, but does not eliminate the hazard”

In many sectors, from construction and industry to healthcare and maritime transport, personal protective equipment (PPE) has become indispensable. Helmets, gloves, safety glasses, and respiratory protection are often the most visible aspects of occupational safety. In the maritime sectors, life jackets are also added to this list. However, it is important to realize that PPE is not the starting point, but rather the end point of a responsible occupational health and safety policy. This principle is enshrined in Dutch working conditions legislation, which includes an occupational health strategy.

Legal framework: duty of care and prevention

The Working Conditions Act (Arbowet) obliges employers to ensure safe and healthy working conditions. This duty of care goes beyond simply providing protective equipment. Employers must systematically identify risks through a risk inventory and evaluation (RI&E) and then take measures to control these risks.

at Sea!

Join Work Safely at Sea and help us spread the important message about safety further. We are looking for companies, ships, and workers to share their experiences. Your story can inspire others and make them aware of the crucial role safety plays in our work. Whether you have a success story or a lesson learned from a near miss, your contribution can make a difference. Fill in the form and join our mission to make the sea a safer place to work for everyone

“True safety begins with eliminating risks at the source. PPE is the last, but sometimes necessary, line of defense”

“Personal protective equipment protects the employee, but does not eliminate the hazard”

Conclusion

Personal protective equipment plays an indispensable role in protecting employees, but only within the right framework. Occupational health and safety strategy and working conditions legislation make it clear that true safety begins with eliminating risks at source. PPE is the last, but sometimes necessary, line of defense. Respecting this order not only creates a safer workplace, but also a more sustainable and professional safety policy.

Responsible use in practice

When PPE is necessary, the Working Conditions Act sets clear requirements. The employer must provide suitable equipment, tailored to the risk and the wearer. In addition, instruction is mandatory: employees must know when, how, and why they use PPE. Maintenance and replacement are also crucial; worn or contaminated equipment loses its protective effect.

Employees, in turn, have a duty to actually use PPE and to handle it with care. After all, working safely is a shared responsibility.

Why PPE is the last resort

Personal protective equipment protects the employee, but does not eliminate the danger. Moreover, it is highly dependent on correct use. Safety glasses that do not fit properly, a mask that is worn incorrectly, gloves that are not replaced in time, or a life jacket whose crotch strap is not used, offer a false sense of security.

PPE can also be burdensome: it can make work more difficult, restrict vision, or reduce comfort. This increases the likelihood that it will not be used consistently. That is precisely why the legislator emphasizes that PPE should never be an excuse for neglecting source or collective measures.

The law is clear on this point: risks should preferably be addressed at source. Only when this is not possible may additional measures be taken. Personal protective equipment is permitted, but only if other solutions do not offer sufficient protection.

The occupational health strategy as a guideline

The occupational health strategy is the framework that helps you make the right choices in risk management. This strategy consists of a fixed sequence of measures:

Source approach

Eliminating the hazard itself, for example by replacing a harmful substance with a less hazardous alternative or by replacing a noisy machine.Collective technical measures

These include extraction systems, sound insulation, or physical shielding that protects multiple employees at the same time.Organizational measures

These include limiting exposure time, job rotation, or adjusting work processes.Personal protective equipment

PPE only comes into play when the above steps are insufficient.

This order is not arbitrary. It reflects the principle that structural solutions are more sustainable and reliable than protection that depends on individual behavior.

In many sectors, from construction and industry to healthcare and maritime transport, personal protective equipment (PPE) has become indispensable. Helmets, gloves, safety glasses, and respiratory protection are often the most visible aspects of occupational safety. In the maritime sectors, life jackets are also added to this list. However, it is important to realize that PPE is not the starting point, but rather the end point of a responsible occupational health and safety policy. This principle is enshrined in Dutch working conditions legislation, which includes an occupational health strategy.

Legal framework: duty of care and prevention

The Working Conditions Act (Arbowet) obliges employers to ensure safe and healthy working conditions. This duty of care goes beyond simply providing protective equipment. Employers must systematically identify risks through a risk inventory and evaluation (RI&E) and then take measures to control these risks.

Foto: KVNR

Join Work Safely at Sea and help us spread the important message about safety further. We are looking for companies, ships, and workers to share their experiences. Your story can inspire others and make them aware of the crucial role safety plays in our work. Whether you have a success story or a lesson learned from a near miss, your contribution can make a difference. Fill in the form and join our mission to make the sea a safer place to work for everyone

at Sea!

een veilige en productieve plek voor iedereen"